Concrete is a fundamental part of modern infrastructure, forming the backbone of roads, sidewalks, driveways, and buildings. But over time, wear and tear, environmental effects, and structural pressures cause concrete surfaces to deteriorate. Fortunately, affordable concrete surface damage repair solutions are available that can extend the lifespan of your concrete without breaking the bank. In this article, we’ll explore the causes of common concrete damage and 10 expert, budget-friendly methods to fix it effectively.

Introduction to Concrete Surface Damage

Concrete surfaces are subjected to daily stress, from foot traffic to extreme weather. Over time, they can develop cracks, chips, and other types of damage that affect both their function and appearance. Understanding concrete surface damage is essential for homeowners, contractors, and property managers who want to maintain the structural integrity and aesthetic appeal of their spaces.

Concrete repair might seem daunting or expensive, but the good news is that many affordable concrete surface damage repair solutions exist. With timely intervention and the right techniques, you can prevent small problems from turning into costly replacements.

Common Types of Concrete Surface Damage

Before diving into repair methods, let’s take a look at the most frequent types of damage that affect concrete surfaces:

- Cracks: Often caused by shrinkage, temperature changes, or structural load.

- Scaling: The surface flakes or peels away, usually from freeze-thaw cycles or poor finishing.

- Spalling: Deeper surface layers break off, exposing aggregates.

- Chipping: Small chunks of concrete break off from edges or corners.

- Discolouration: Stains or fading due to exposure and chemical reactions.

Each damage type demands a slightly different repair approach, and knowing the specifics helps in selecting the right solution.

Causes of Concrete Surface Damage

Understanding the root causes is crucial to prevent recurrence after repair. Here are some common causes:

- Freeze-Thaw Cycles: Water seeps into concrete, freezes, expands, and causes cracks.

- Poor Installation: Incorrect mixing, finishing, or curing can weaken concrete.

- Heavy Loads: Excessive weight or vibration damages the surface.

- Chemical Exposure: Deicing salts, oils, and acids degrade concrete.

- Aging: Natural wear over time reduces strength and appearance.

By addressing these causes, repairs can last longer and maintain the durability.

Benefits of Timely Concrete Repair

Repairing concrete damage promptly has several advantages:

- Cost Savings: Small repairs are cheaper than full replacements.

- Safety: Prevent accidents caused by uneven or crumbling surfaces.

- Aesthetics: Maintains curb appeal and property value.

- Durability: Extends the functional life of concrete.

- Environmental Impact: Reduces waste and resource use.

Delaying repairs can lead to more extensive damage and higher costs.

Assessing the Damage: When to Repair or Replace

Not all concrete damage warrants repair. Sometimes, replacement is the better option. Consider these criteria:

| Factor | Repair Recommended | Replacement Recommended |

|---|---|---|

| Crack Width | < 1/4 inch | > 1/4 inch or structural cracks |

| Depth of Damage | Surface or shallow | Deep or through entire slab |

| Extent of Damage | Localized | Widespread or multiple areas |

| Underlying Cause | Correctable (e.g., seal leaks) | Structural failure or sinking |

Professional evaluation may be necessary for significant issues.

Affordable Concrete Repair Materials

Choosing the right materials keeps repairs cost-effective. Common affordable options include:

- Polymer-modified mortars: Flexible and strong for patching.

- Epoxy resins: Ideal for crack injection and bonding.

- Cementitious overlays: Thin layers to resurface and protect.

- Concrete sealers: Prevent moisture and chemical intrusion.

Balancing cost and quality ensures long-lasting repairs without overspending.

Method 1: Crack Injection Technique

Crack injection is a precise way to repair narrow cracks by filling them with epoxy or polyurethane. This method restores structural integrity and prevents water intrusion.

Steps:

- Clean the crack thoroughly.

- Insert injection ports along the crack.

- Inject the epoxy/polyurethane under pressure.

- Allow curing before removing ports.

Best for cracks less than 1/4 inch wide and can be done affordably by professionals or skilled DIYers.

Method 2: Surface Patching and Resurfacing

When concrete surfaces have minor chips or shallow damage, patching with polymer-modified mortar followed by resurfacing is effective.

Process:

- Remove loose debris.

- Apply bonding agent.

- Fill damaged areas with patch material.

- Smooth surface and apply overlay if needed.

This method improves appearance and durability at a low cost.

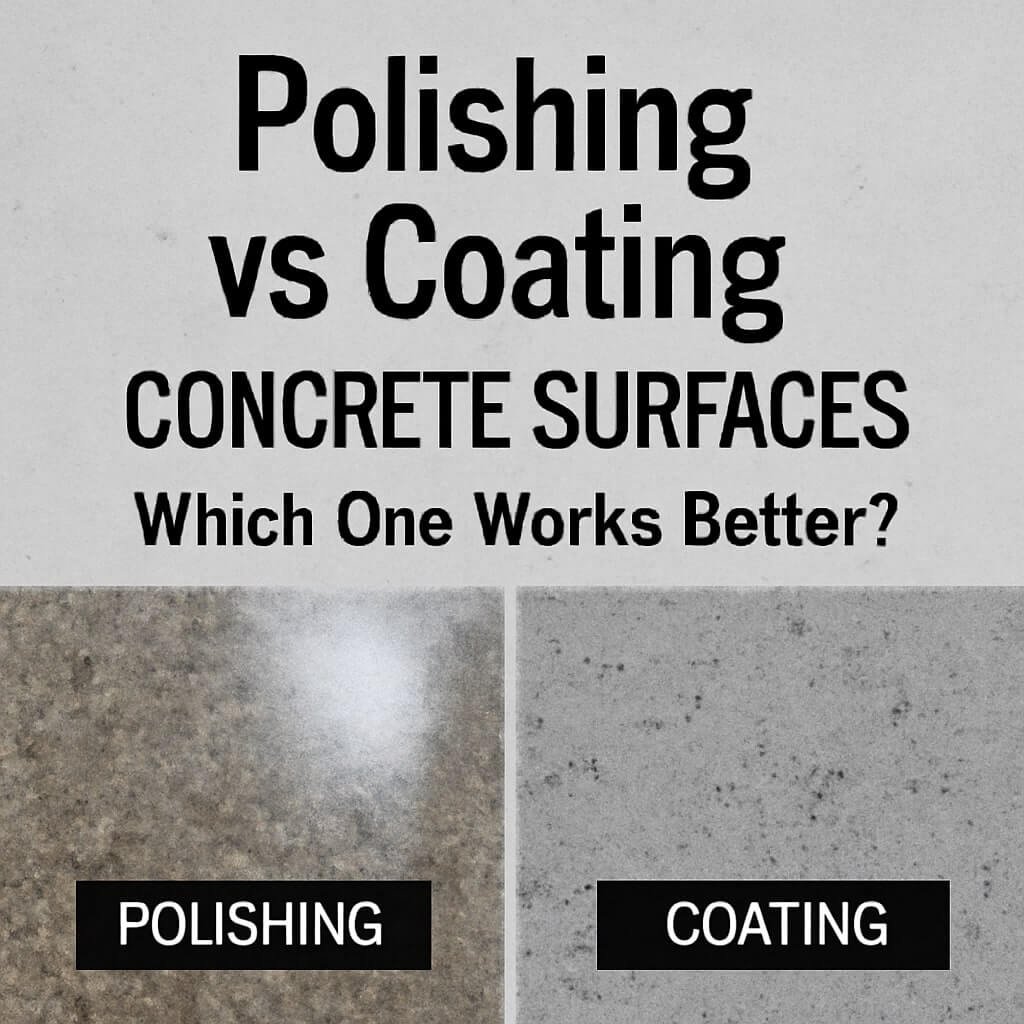

Method 3: Epoxy and Polyurethane Coatings

Applying protective coatings helps seal and protect concrete surfaces from moisture, chemicals, and wear.

- Epoxy coatings: Provide a hard, durable surface ideal for garages and industrial floors.

- Polyurethane coatings: Offer flexibility and UV resistance, good for outdoor areas.

Coatings are affordable, easy to apply, and extend concrete life.

Method 4: Concrete Overlay Installation

Concrete overlays are thin layers applied to existing slabs to improve surface texture and appearance. They can mask defects and provide a fresh finish.

Advantages:

- Cost-effective compared to full replacement.

- A variety of finishes and colours are available.

- Can include anti-slip additives for safety.

Ideal for driveways, patios, and walkways needing cosmetic and structural improvement.

Method 5: Grinding and Polishing

Grinding removes surface imperfections and prepares concrete for coatings or overlays. Polishing enhances aesthetics and durability, making concrete smooth and shiny.

Benefits:

- Affordable surface restoration.

- Improves slip resistance.

- Reduces dust and maintenance needs.

This technique is popular for commercial and residential flooring.

DIY vs Professional Repairs: Pros and Cons

DIY Repairs:

- Lower labor costs.

- Immediate action on small problems.

- Requires research and effort.

Professional Repairs:

- Expert assessment and long-lasting results.

- Access to specialized tools and materials.

- Higher upfront cost but better value long-term.

Deciding depends on damage extent, budget, and skill level.

Maintenance Tips to Prolong Concrete Life

Keeping concrete in top shape reduces the need for costly repairs:

- Seal concrete regularly.

- Clean spills promptly.

- Avoid harsh chemicals.

- Control drainage around slabs.

- Repair minor cracks immediately.

Routine care pays off with longer-lasting surfaces.

Frequently Asked Questions (FAQs)

1. How much does affordable concrete repair typically cost?

2. Can I repair concrete damage myself?

3. How long do concrete repairs last?

4. Is it necessary to seal concrete after repair?

5. What causes concrete to crack the most?

6. Are there eco-friendly concrete repair options?

Conclusion: Choosing the Right Affordable Repair Solution

Concrete surface damage can seem intimidating, but with the right knowledge and affordable repair solutions, restoring your concrete is well within reach. From crack injections and patching to overlays and protective coatings, these methods provide effective, budget-friendly options to maintain durability, safety, and aesthetics. Don’t wait for damage to worsen — timely repairs save money and extend the life of your concrete surfaces.