Nanotechnology is shaking up the construction industry in profound ways, especially when it comes to enhancing concrete. For years, concrete has been the backbone of infrastructure worldwide, but it isn’t without its flaws. Thanks to nanotechnology, we’re witnessing a revolution—one that improves the material’s strength, durability, and environmental footprint. This article explores 12 cutting-edge innovations that showcase how nanotechnology is revolutionising concrete enhancement, pushing the limits of what’s possible in construction.

Understanding Concrete and Its Limitations

Common Challenges in Traditional Concrete

Concrete is a composite material made primarily of cement, water, and aggregates. Despite its widespread use, traditional concrete faces challenges such as:

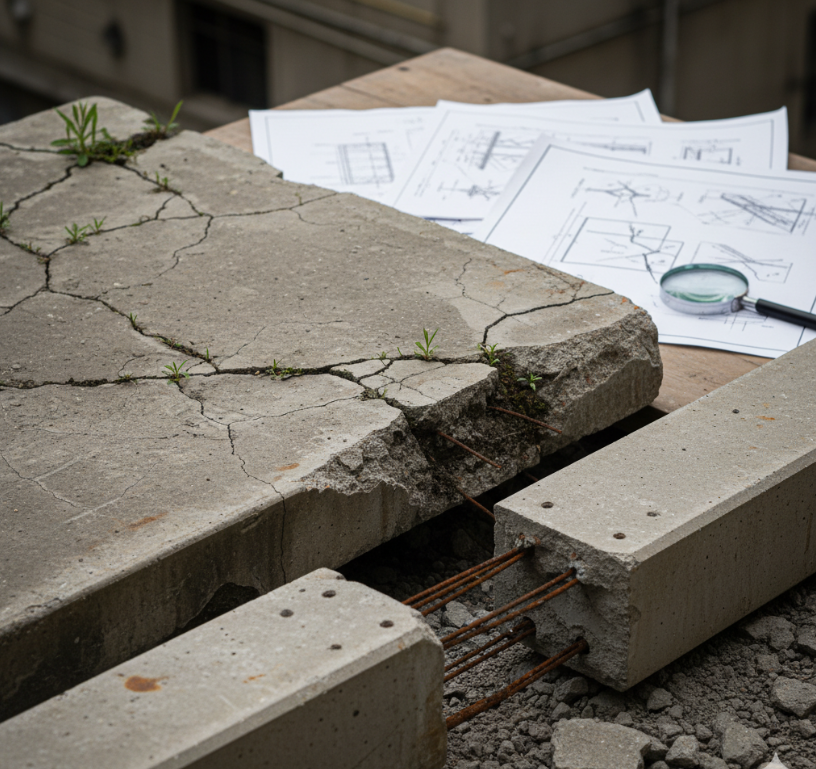

- Cracking due to shrinkage and thermal stresses

- Durability issues from chemical attacks (e.g., sulphates, chlorides)

- Porosity, which leads to water infiltration and corrosion of steel reinforcements

- Long curing times that delay construction schedules

These limitations have long been a concern for engineers and builders, prompting the search for materials and technologies to enhance concrete’s performance.

What is Nanotechnology?

Nanotechnology deals with materials at the nanoscale (1 to 100 nanometers), where unique physical and chemical properties emerge. When applied to concrete, these nanoscale additives can significantly alter the behaviour of the material by improving the microstructure and chemical reactions during curing.

Nanomaterials Commonly Used in Concrete Enhancement

Several nanomaterials have gained traction in the construction world:

- Nano-silica

- Carbon nanotubes

- Nano-titanium dioxide

- Nano-clay

- Graphene oxide

Each of these plays a distinct role in enhancing concrete’s physical and chemical properties.

How Nanotechnology Enhances Concrete Properties

Increased Strength and Durability

Nanomaterials fill in the microscopic voids in concrete, making the matrix denser and stronger. For example, nano-silica improves compressive strength by accelerating cement hydration and refining the pore structure.

Improved Workability and Setting Time

Certain nanoparticles can reduce water demand while maintaining flowability, leading to better workability and faster setting times.

Enhanced Resistance to Cracking and Environmental Damage

Nanomaterials such as carbon nanotubes enhance tensile strength and toughness, reducing cracking. Meanwhile, nano-titanium dioxide offers photocatalytic properties that help degrade pollutants and resist microbial growth.

12 Groundbreaking Nanotechnology Innovations in Concrete

1. Nano-silica

Nano-silica is one of the most widely used nanoparticles in concrete. It acts as a pozzolanic material, enhancing strength and reducing permeability.

2. Carbon Nanotubes

Carbon nanotubes (CNTs) significantly boost tensile strength and durability. They act like tiny reinforcing fibres dispersed throughout the concrete.

3. Nano-titanium Dioxide

Besides improving mechanical properties, nano-titanium dioxide provides self-cleaning and air-purifying abilities through its photocatalytic activity.

4. Nano-clay

Nano-clays improve the barrier properties of concrete, making it more resistant to moisture and chemical penetration.

5. Nano-alumina

Nano-alumina enhances the early strength and hardness of concrete and improves abrasion resistance.

6. Graphene Oxide

Graphene oxide is a superstar additive that dramatically increases both strength and flexibility, creating more resilient concrete composites.

7. Nano-calcium Carbonate

This additive accelerates cement hydration, leading to faster setting and higher early strength.

8. Nano-iron Oxide

Nano-iron oxide enhances the durability and corrosion resistance of concrete, especially in harsh environments.

9. Nano-zinc Oxide

It provides antimicrobial properties and helps protect concrete surfaces from fungal and bacterial growth.

10. Nanocellulose

Derived from plant fibres, nanocellulose improves toughness and crack resistance by enhancing the concrete’s internal fiber network.

11. Nano-silica Fume

A byproduct of silicon metal production, nano-silica fume improves compressive strength and durability by filling micro-pores.

12. Nanostructured Polymers

These polymers improve flexibility and adhesion properties, offering enhanced resistance to cracking and chemical attack.

Environmental and Economic Benefits of Nanotechnology in Concrete

Sustainability and Reduced Carbon Footprint

Nanotechnology contributes to sustainability by enabling the production of stronger concrete with less material, lowering carbon emissions associated with cement production.

Cost Efficiency and Lifecycle Benefits

While initial costs may be higher, nanotechnology-enhanced concrete offers longer service life and reduced maintenance, delivering economic benefits over the long term.

Challenges and Future Directions in Nanotechnology for Concrete

Safety and Health Concerns

The use of nanoparticles raises questions about health risks during production and handling, necessitating strict safety protocols.

Scaling Up and Commercialisation

Despite promising lab results, large-scale adoption faces hurdles such as cost, standardisation, and regulatory approval.

Frequently Asked Questions (FAQs)

1. How does nanotechnology improve the strength of concrete?

2. Are nanomaterials in concrete safe for workers and the environment?

3. Can nanotechnology make concrete more sustainable?

4. How much does nanotechnology-enhanced concrete cost compared to traditional concrete?

5. What are the most common nanomaterials used in concrete?

6. Is nanotechnology widely available commercially?

Conclusion

Nanotechnology is undeniably revolutionising concrete enhancement, offering exciting innovations that improve strength, durability, and sustainability. As research progresses and industry adoption grows, the future of concrete looks stronger, smarter, and greener. This transformation not only benefits construction but also supports global efforts toward sustainable development.