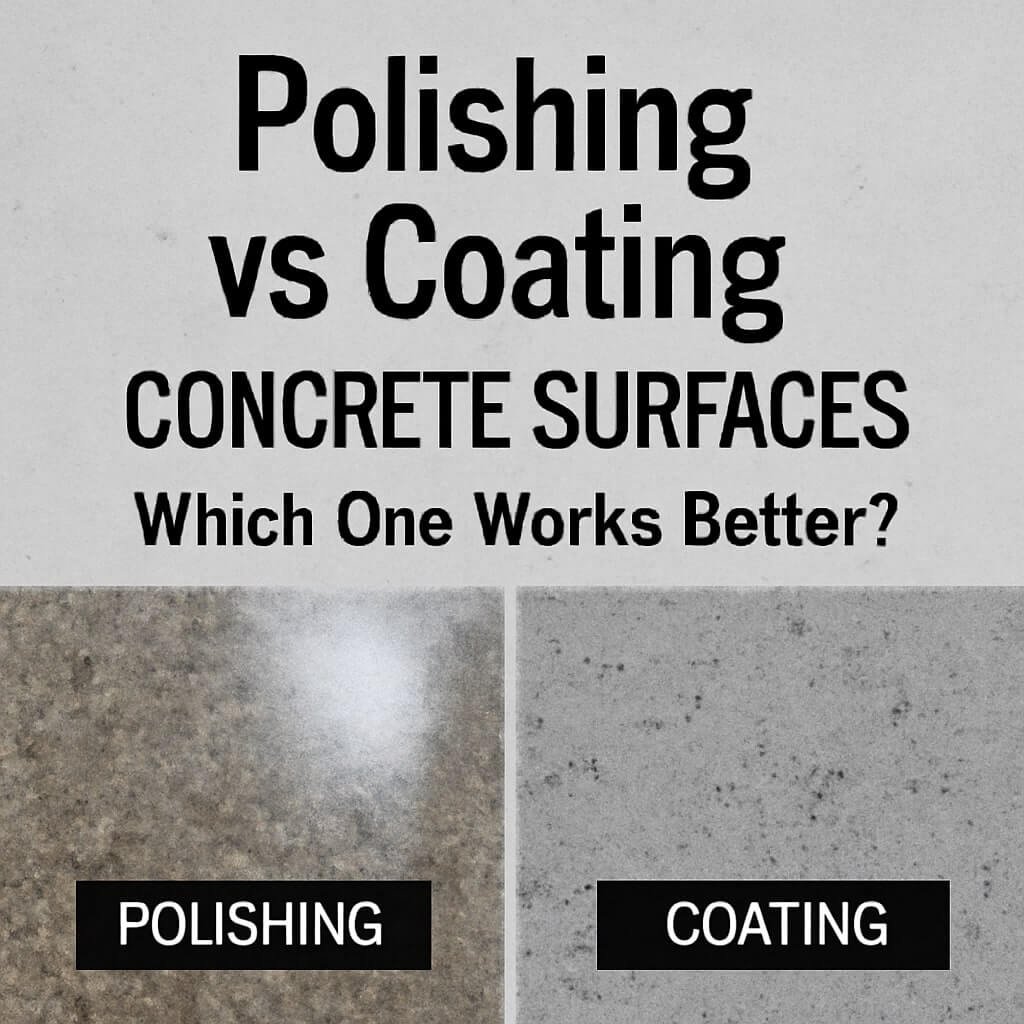

Concrete is a fundamental material in construction, admired for its strength and versatility. When it comes to finishing concrete surfaces, two popular options often stand out: polishing and coating. But which one truly works better? This detailed guide explores the nuances of polishing vs coating concrete surfaces, helping you make an informed choice tailored to your needs.

Understanding Concrete Surface Treatments

Before diving into the comparison, let’s clarify what polishing and coating entail in the context of concrete finishing.

What Is Concrete Polishing?

Concrete polishing is a mechanical process that grinds down the surface of the concrete using progressively finer abrasive tools. This reveals the aggregate inside and results in a smooth, glossy, and durable finish. The process involves multiple stages, starting with coarse grinding and ending with polishing to achieve a mirror-like sheen.

What Is Concrete Coating?

Concrete coating refers to applying a protective layer or sealant on top of the existing concrete surface. Coatings can be made from epoxy, polyurethane, acrylic, or other materials designed to protect, color, and enhance concrete. Unlike polishing, coating covers the surface rather than altering the concrete structure itself.

Key Differences Between Polishing and Coating

Understanding the fundamental differences is crucial when choosing between polishing and coating.

Durability and Longevity

Polished concrete is highly durable because it’s essentially grinding down to a hardened surface that resists wear and tear naturally. Coatings, while protective, may degrade over time and require reapplication to maintain their effectiveness.

Aesthetic Appeal

Polishing reveals the natural beauty of concrete, including aggregates and textures, resulting in a sleek, modern look. Coatings offer more flexibility in color and design, allowing for bold patterns, textures, or even non-slip finishes.

Maintenance Requirements

Polished concrete is relatively low-maintenance, requiring only occasional cleaning and resealing every few years. Coated surfaces may demand more frequent maintenance, including cleaning and recoating, especially in high-traffic or outdoor areas.

Cost Comparison

Initial costs for polishing can be higher due to equipment and labor intensity. Coatings might be less expensive upfront but can incur ongoing maintenance costs over time.

Advantages of Polishing Concrete

- High durability and long lifespan

- Natural, glossy finish that improves over time

- Resistant to stains and abrasion

- Environmentally friendly with no added chemicals

- Low maintenance and cost-effective in the long run

Advantages of Coating Concrete

- Wide variety of colors, textures, and finishes

- Quick application process

- Enhances protection against chemicals, moisture, and UV rays

- Can provide non-slip surfaces for safety

- Ideal for covering imperfections or damaged concrete

Best Use Cases for Polishing

Polishing is excellent for indoor areas like warehouses, retail stores, schools, and offices, where a durable, attractive floor is desired without the need for frequent recoating.

Best Use Cases for Coating

Coatings suit outdoor patios, garages, industrial floors, and areas exposed to harsh chemicals or weather, where additional protection and design options are essential.

Common Mistakes to Avoid

- Choosing polishing for outdoor areas exposed to harsh weather without proper sealing

- Applying coatings on wet or unprepared surfaces, leading to peeling

- Neglecting maintenance and inspections after treatment

- Overlooking the intended use of the space and choosing the wrong finish

Environmental Impact

Polishing concrete is often considered more sustainable due to the lack of chemical use and longer lifespan. Some coatings contain volatile organic compounds (VOCs), impacting indoor air quality and the environment. Choosing low-VOC or eco-friendly coatings can mitigate this issue.

Step-by-Step Process: How to Polish Concrete

- Prepare the surface by cleaning and repairing cracks.

- Coarse grinding with diamond abrasives to remove the surface layer.

- Progressive grinding with finer grits for smoothness.

- Apply densifier to harden the surface.

- Final polishing to achieve desired gloss.

- Sealing (optional) to enhance stain resistance.

Step-by-Step Process: How to Coat Concrete

- Clean and prepare the surface thoroughly.

- Repair any cracks or damage.

- Apply primer if necessary.

- Mix and apply coating evenly with brushes or rollers.

- Allow drying and cure times as specified.

- Apply additional coats if needed.

Frequently Asked Questions (FAQs)

Is polished concrete more durable than coated concrete?

Can I apply coating on polished concrete?

How long does each treatment last?

Which option is better for outdoor surfaces?

Are there any health risks associated with coatings?

How do I maintain polished or coated concrete surfaces?

Conclusion: Choosing the Right Concrete Surface Treatment

Both polishing and coating have unique strengths. If you want a long-lasting, natural finish with minimal upkeep, polishing is the way to go. For maximum protection, color options, and surface versatility, coatings might be better. Consider your environment, budget, and aesthetic preferences carefully to make the best choice.